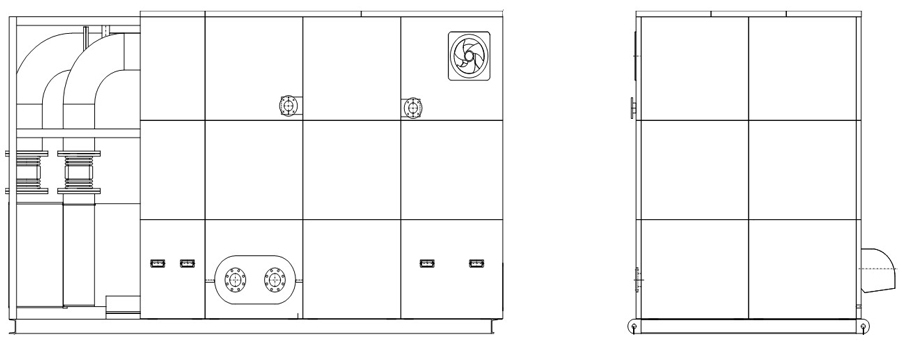

Large capacity air-cooler (N2) flow chart of brine refrigeration system

Tokyo, March 10, 2022 – Mitsubishi Heavy Industries Air-Conditioning and Refrigeration Corporation (MHI-AC&R), a Mitsubishi Heavy Industries, Ltd. group company. (MHI), recently developed a large-capacity brine refrigeration system adopting nitrogen (N2) refrigerant having both zero ozone depletion potential (ODP) (Note1) and zero global warming potential (GWP) (Note2). The new system can even meet cryotemperature needs, placing it at the top of the industry’s offerings (Note3). The company has just delivered one unit of the new system to The Honjo Chemical Corporation (Neyagawa, Osaka), a manufacturer of organic chemicals and other products, and further domestic sales will be pursued in the future.

The new system can refrigerate at ultra-low and cryogenic temperatures (brine temperature: -45℃ to -100℃) through the application of MHI-AC&R’s exclusive (patented) air refrigeration cycle technology. The unit also features one of the most compact sizes in the industry, allowing for easy handling and transportation. Its compression-expanding machine integrates the high technologies accumulated by MHI Group in gas turbines. In addition to capturing the energy generated during air expansion cooling and using it as drive power, stable operation is achieved through the integration of state-of-the-art technologies such as energy-saving inverter control of energy.

The new refrigeration system contributes significantly to curbing global warming through the adoption of N2, a natural refrigerant with zero environmental impact. In recent years, initiatives to prevent climate change have accelerated. In Japan, since April 2015, when the Fluorocarbon Rational Use and Appropriate Management Law(Note4) came into force, the low temperature refrigeration machine market has been urged to adopt low temperature refrigerants. GWP. At the international level, alongside the implementation of the Kigali Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer in January 2019, as well as revisions to the Vienna Convention for the Protection of the ozone layer, the production of chlorofluorocarbon (CFC) substitutes and the gradual reduction of energy consumption have become mandatory.

Today, as there are few refrigerant options in the field of ultra-low temperature refrigeration, many refrigeration systems continue to use CFC refrigerants. However, the demand for CFC-free refrigeration systems is steadily increasing in order to lessen the impact on the environment. The refrigerant used in MHI-AC&R’s new refrigeration system uses nitrogen, which is approximately 78% of the air content, so it is safe for the environment and for humans. The use of CFC-free refrigerant also eliminates the inspection procedures required by the Fluorocarbon Rational Use and Proper Management Law, and the new refrigerant is also exempt from the High Pressure Gas Safety Law. which regulates the production of high pressure gases and their consumption, etc. Another benefit is the adoption of magnetic bearings in the system’s compression expander machine, which eliminates the need for lubricating oil and allows for virtually unlimited life, helping to alleviate maintenance and maintenance burdens. user operation.

■ Refrigerant comparisons

| Type of refrigerant | Refrigerants used in very low temperature CFC refrigeration systems | Natural refrigerant (air) |

||||

|---|---|---|---|---|---|---|

| HCFCs | HFCs | |||||

| R22 | High temperature | Low temperature | High temperature | Low temperature | ||

| R404A | R23 | R23 | R32 | NOT2 | ||

| ODP(Note1) | 0.05 | 0 | 0 | 0 | 0 | 0 |

| GWP(Note2) | 1,810 | 3,920 | 14,800 | 1,495 | 675 | 0 |

| High Pressure Gas Safety Act | In force | Exempt | ||||

Going forward, MHI-AC&R will continue to promote cooling systems that use natural refrigerants, which have zero ODP and GWP, as a way to contribute to global environmental protection in the cryo-temperature refrigeration market. . Sales expansion efforts will focus in particular on domestic chemical and fine chemical manufacturers.

Refrigeration system installation picture

- 1ODP is a coefficient expressing the ozone depletion potential of a refrigerant compared to the previously widely used CFC-11 (trichlorofluoromethane), which is assigned a value of 1.0. The lower the ODP value, the lower the deleterious impact on the ozone layer.

- 2The GWP is a coefficient expressing the global warming potential of a refrigerant compared to CO2, which is assigned the value 1.0. The lower the GWP, the higher the environmental performance of the refrigerant.

- 3Based on MHI-AC&R internal survey.

- 4The Rational Use and Proper Management of Fluorocarbons Act is a fully revised update, made in April 2015, of the original Fluorocarbons Recovery and Destruction Act enacted in 2001. Under the revised legislation, the Commercial refrigeration condensing units and stationary refrigeration units with a refrigeration system capacity greater than 1.5 kilowatt (kW) (approximately 2 HP) are required by 2025 to adopt refrigerants with a GWP less than 1500 ( CO2 =1).

Delivery overview

Client and Destination: The Honjo Chemical Corporation, Naoshima Organic Chemical Plant

(Naoshima-cho, Kagawa-gun, Kagawa Pref.)

Intended use: removal of the heat of reaction produced during the production of organic chemicals

Specification: brine temperature -80℃ (down to -100℃)

Woodkirk Stone

Woodkirk Stone